Rapidly growing battery graphite market

26.8 million

light duty EVs expected to be sold by 2030.

Platts Analytics 2022

30%

expected annual increase in graphite demand from the battery sector until 2030.

S&P Global 2022

91%

of the world’s lithium-ion battery anode production is controlled by China.

Benchmark 2022

CarbonScape biographite meets global demand with a sustainable solution.

Benefits of our biographite

High purity

The environmentally friendly, low temperature CarbonScape process creates a biographite with a purity equivalent to costly high temperature thermal treatments.

The material has a final purity in excess of 99.95 wt% carbon. Individual impurities are present below 50 parts per million.

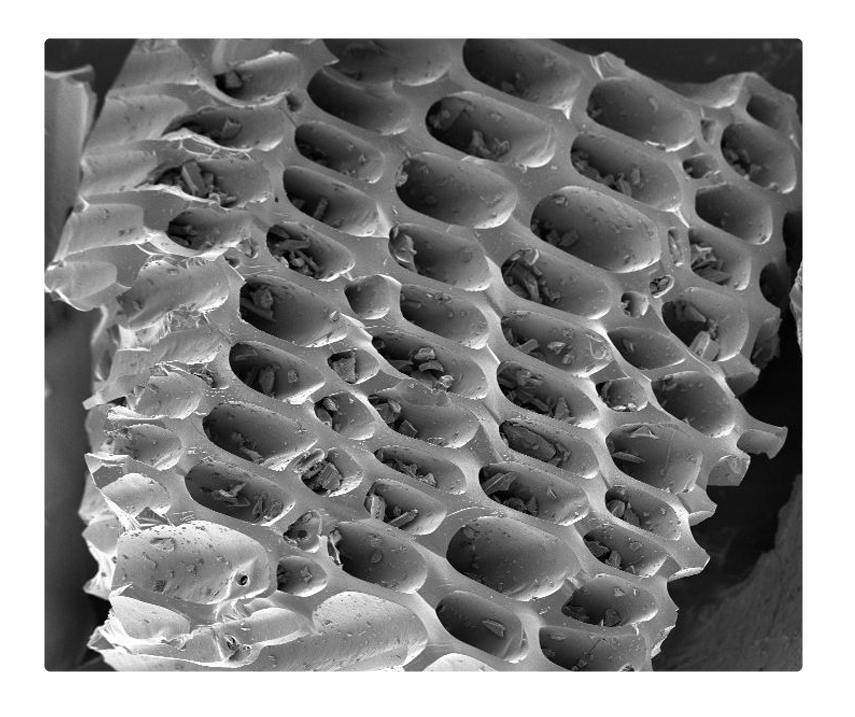

Consistently superior quality

CarbonScape’s patented process delivers high quality biographite every time, overcoming the inherent variations found in natural biomass.

In contrast, mined fossil graphite can vary tremendously through a single deposit. Traditional synthetic graphite, which is made by polymerizing petroleum molecules, has steric limitations. It cannot achieve the large, high quality crystallites found in CarbonScape biographite.

Net negative biographite anode

By using forest and timber industry byproducts as our feedstock, we permanently sequester the CO₂ held within the biomass.

During the production process to make our biographite, a minimal amount of CO₂ is returned to the atmosphere. However, this amount is significantly less than we remove, creating the world’s only net negative biographite anode.

Higher capacity, faster charging

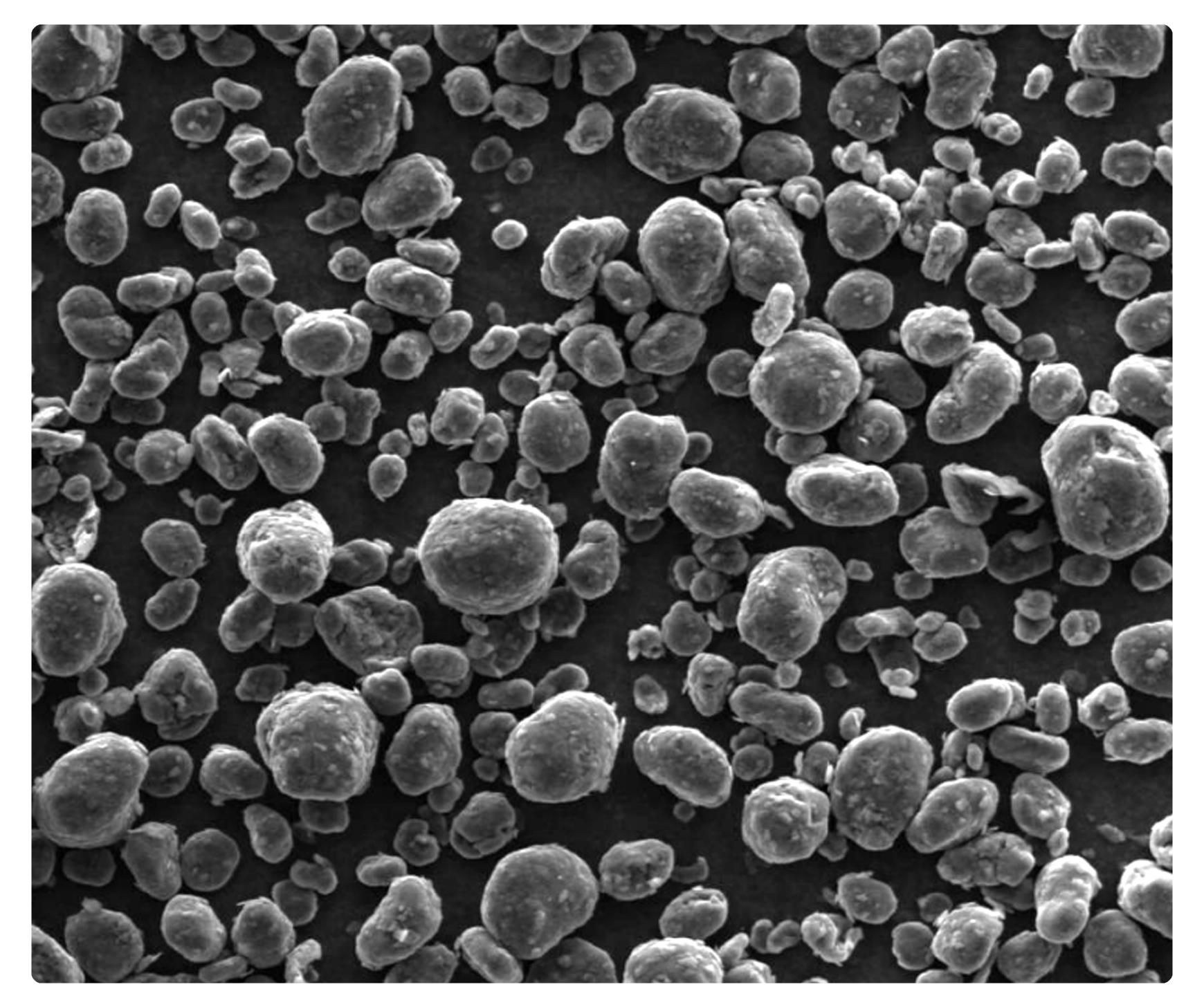

With its high levels of crystallinity, CarbonScape biographite anode has greater capacity than synthetic graphite (>360 mAh/g).

Its unique microstructure allows rapid movement of lithium ions, providing superior fast charge capacity (>60% capacity retention at 2C) compared to natural graphite.

Proven cell performance

CarbonScape biographite anode performance has been verified by leading cell manufacturers. The material tested in real world, multi-layer cells up to several Ah in size, using both LiNiMnCoO2 (NMC) and LiCoO2 (LCO) cathodes.

Our biographite anode compares well to all electric vehicle (EV) and other market specifications. The cells have undergone hundreds of cycles without significant reduction in capacity, at 25⁰C and 45⁰C.

Fast, localised production

CarbonScape technology can be applied almost anywhere and allows for fast and continuous production. Our biographite is available immediately, when you need it.

This will more readily and affordably feed the growing anode demand centres of Europe and North America, without the emissions and risk associated with a long, centralised supply chain.

We combine the crystalline perfection of natural graphite with the predictable consistency of a production process.

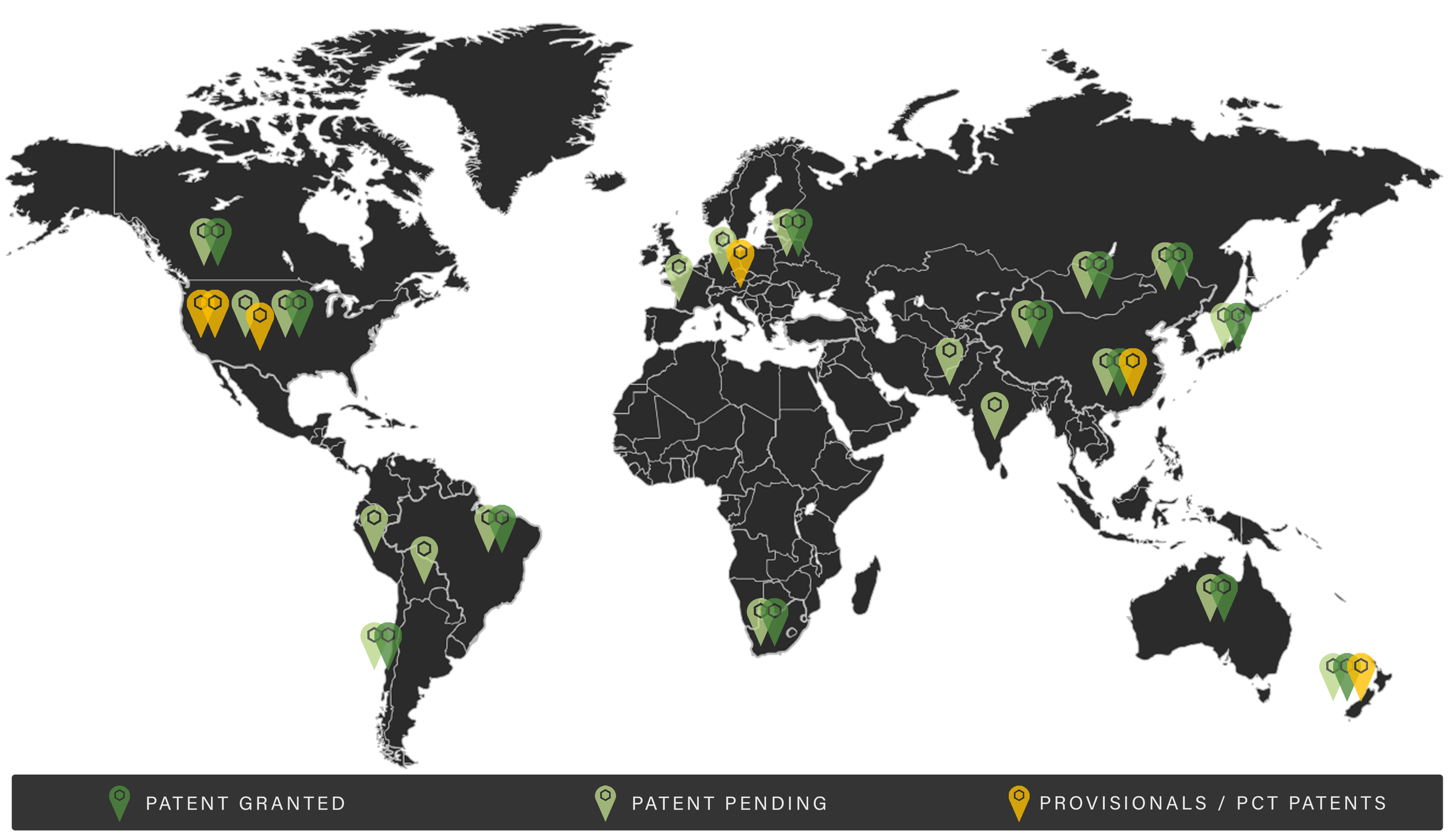

Our patented technology

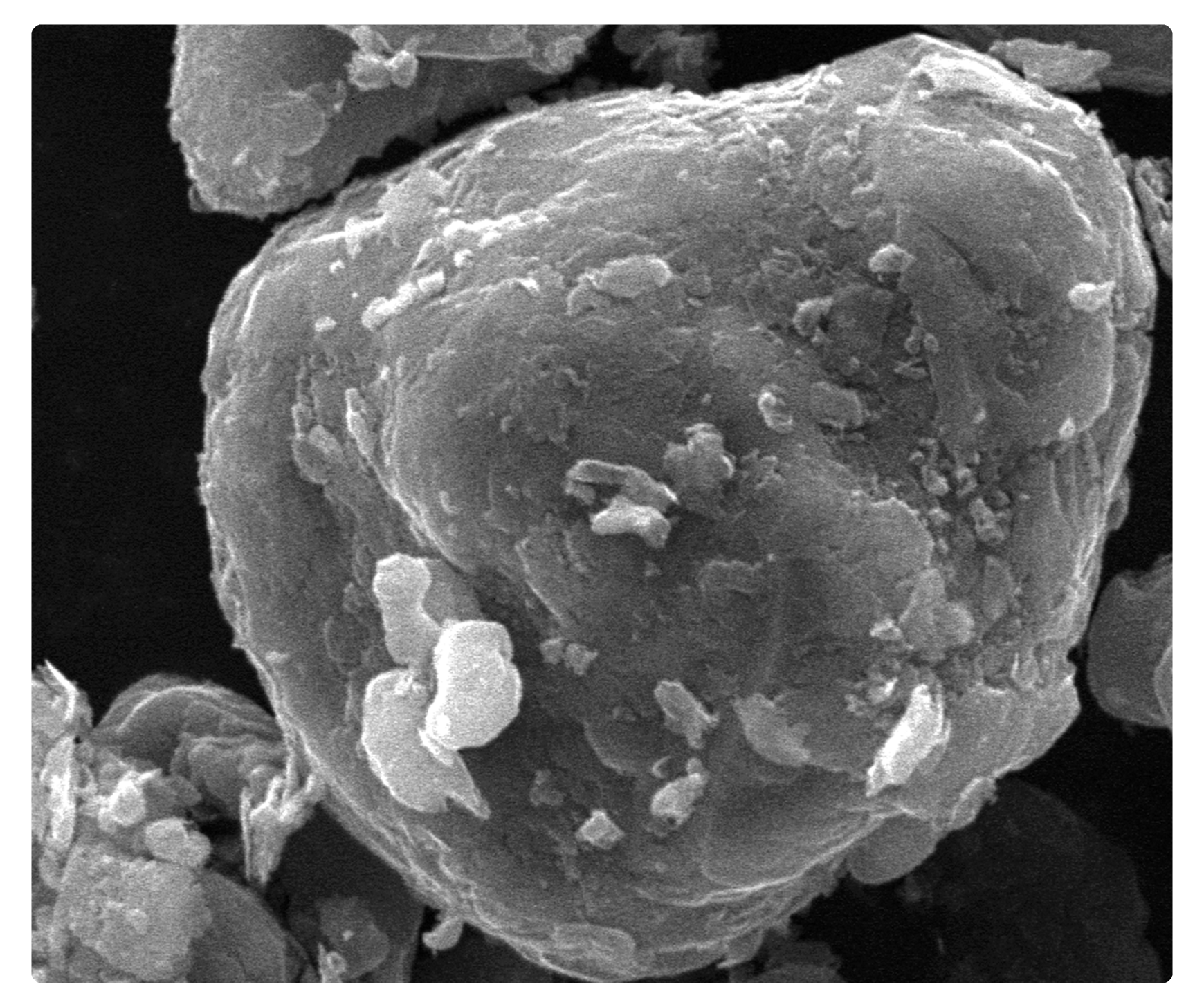

CarbonScape’s cutting-edge, patented thermo-catalytic technology transforms the amorphous carbon in biomass into battery-grade biographite.

The technology ensures consistently high-quality, specifically tailored biographite anode material with a unique combination of properties.

The process uses a fraction of the time and cost compared to traditional synthetic graphite processes.

3 x

Patent families

Proprietary process

250

Trade secrets

Untraceable chemical additive

>250

Patents around the world

Cannot be reverse engineered

Product development

Our premium pilot facility demonstrates the processes required for commercial-scale production of CarbonScape biographite.

With quality control analysis on all core processing steps, our team of experts provides the necessary scale-up data for biographite production anywhere in the world. This is supported by off-site vendor testing and third party engineering partners.

Product development capabilities and equipment

Facilities include:

continuous milling.

precision mixing equipment.

high temperature atmospheric controlled furnaces.

purification plant.

biographite anode processing capabilities.

spheroidising and coating.

Analytics capabilities include:

Surface Area Measurement.

Particle Size Distribution.

Trace Impurities.

X-ray diffraction (XRD) analysis

Degree of Graphitisation

Interlayer Spacing

C004/C110 Ratio

Scanning Electron Microscopy.

Ash Content Analysis.

Tapped Density Measurement.

Powder Resistivity Measurement.

Light Microscopy.

Coin Cell Testing.

Pouch Cell Testing.

Advanced capability for manufacturing coin cells and pouch cells.

Testing capacity for both high and low temperatures for both cell types.

Post-mortem analysis of aged cells.

Health, safety and environment

CarbonScape’s facilities are location certified. We uphold high standards of health, safety and environmental quality guidelines.