The ‘seismic change’ to net zero and the growing graphite dilemma

We all know by now that burning fossil fuels is bad for the environment.

In Europe, transport accounts for a quarter of planet-heating emissions, with greenhouse gases from that sector increasing by 7% from 1990 to 2020. In the United States, transportation accounted for 27% of all greenhouse gas emissions in 2020. Of this, more than half came from light duty vehicles.

But, people like driving cars. That’s unlikely to change.

Electrification of the world’s transport fleet is therefore key to reducing fossil fuel emissions. A growing global awareness of this, coupled with rising fuel prices, means that transition is gaining pace.

This can only be sustainable if the materials used for the batteries are sourced sustainably too – especially the material that makes up most of an EV battery, graphite.

The fossil fuel phase-out

Electric vehicles, currently a consumer choice, will eventually become the only choice.

WoodMac chief analyst and chairman Simon Flowers describes EVs as “another measure of the seismic change that achieving net zero will bring about”. He projects 1.7 billion electric vehicles (EVs) will be on the world’s roads by 2050 (90% of all cars), compared to 17 million in 2021.

That change is well underway in key EV markets like Europe, where EVs and plug-in hybrid vehicles comprised 18% of new passenger cars sold in 2021. From 2035, new cars sold in the 27-nation bloc must emit zero CO₂. Britain will ban gasoline car sales even earlier, from 2030.

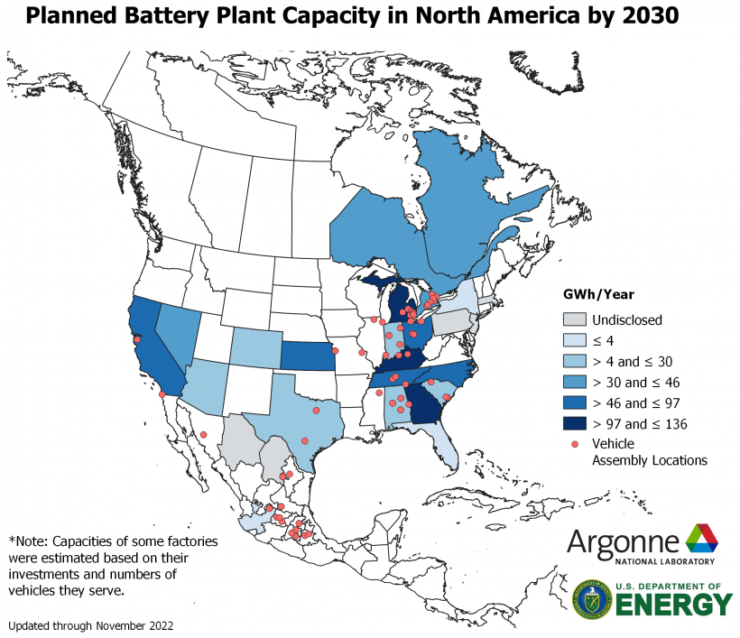

The US and Canadian governments also intend to stop the sale of new combustion engine cars by 2035. In the US, this goal is supported by the recent announcement of 12 new gigafactories, totalling 343 gigawatt hours of capacity. This would grow EV battery manufacturing in North America from 55 gigawatt hours per year (GWh/year) in 2021 to nearly 1,000 GWh/year by 2030 – that’s a 20-fold increase. Canada, too, is building its very first gigafactory.

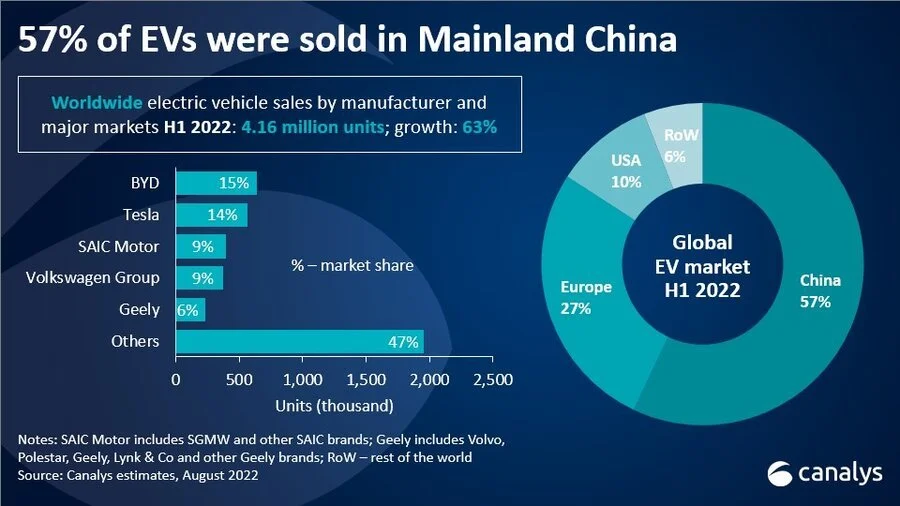

In China, the world’s largest EV market, only Hainan island has announced the nation’s first regional ban on fossil fuel cars by 2030, along with EV tax breaks.

The handbrake: graphite

Graphite anode, an irreplaceable 30% of a lithium-ion battery’s weight, is fast becoming a major dilemma for EV manufacturers.

Demand for graphite anode is forecast to grow by 10.5% annually to 2032. Yet supply is only expected to grow by 5.7% a year over the same period.

Most synthetic graphite for batteries comes from China, the world’s fastest-growing EV market with with 118% year on year growth of sales. Its anode production doubled in the year to November 2022 but, feeding its own burgeoning graphite needs, increasing amounts stay within Chinese borders.

At the same time, governments in the key EV markets of the US and Europe are attempting to shake their reliance on China. America is pushing domestic supply chains legislatively through the 2022 Inflation Reduction Act, while Europe looks set to follow suit with the proposed Green Deal Industrial Plan.

But with no domestic source of graphite anode to draw on, this puts US and EU battery makers in a particularly tricky position. Their supply woes are further compounded by the fact that imported Chinese graphite, made from fossil fuels, will never meet US or European government decarbonisation targets.

The clear market opportunity

Demand for an environmentally sound, domestic source of graphite anode for EV batteries in key regions is clear and it is growing.

CarbonScape is now meeting this readily addressable graphite anode market head-on. Our world-first, net negative CO₂ biographite, engineered for lithium-ion battery anode in EV batteries, is the only material that meets US and EU localisation and decarbonisation targets.

The revolutionary patented technology produces biographite in a process that is fast, continuous and can be applied anywhere in the world, including areas with the cleanest and cheapest energy mixes. This immediately shortens, decarbonises and secures supply chains.

To make our sustainable biographite, we use abundantly available, low-cost waste streams from sustainable forestry and timber (lumber) industries as a renewable feedstock. The CarbonScape proprietary process then turns biomass to biographite in mere hours. At just half the temperature used for traditional synthetic graphite production, and in a fraction of the time, the process is also significantly less energy-intensive.

We are scaling up production and commercialising our biographite technology with partners in Europe and North America. Our mission is to remove the world’s reliance on polluting fossil fuels, mining and at-risk graphite supply chains.

The time to be part of the seismic change to achieve net zero and below is now.